Project Description

Scotts Run, Tyson’s Corner, Virginia

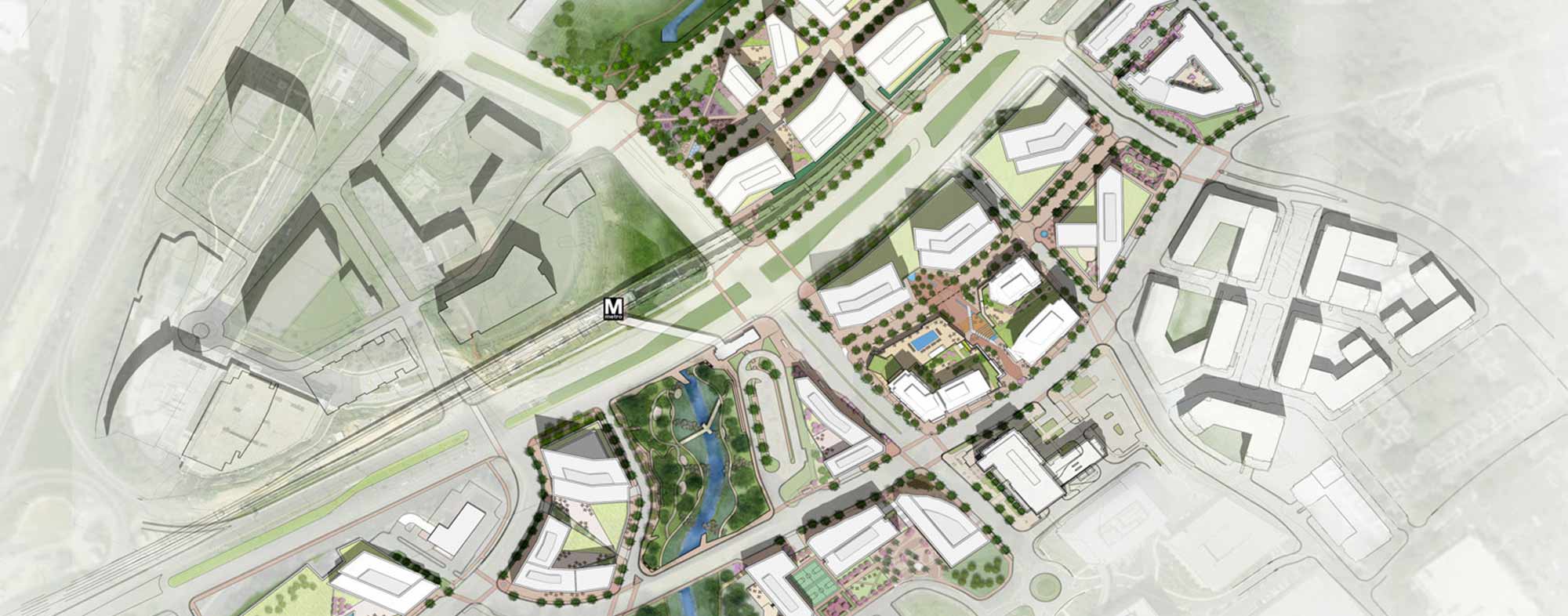

Scotts Run, a major new development in Tyson’s Corner, Virginia involves the ambitious transformation of an auto-centric, suburban environment with aging infrastructure into a walkable, vibrantly urban center of work-life-play

One of the nation’s busiest and most complicated suburban business centers, Tyson’s Corner is undergoing a massive, multi-billion rehabilitation aimed at transforming its existing haphazard design into a carefully orchestrated grid system supporting ambitious new mixed-used development and transportation improvements.

The Anderson Company (TAC) is playing a prominent role in this effort, serving as general contractor of the first phase of the process known as the Scotts Run development effort.

Encompassing 8.5 million square feet spread across nearly 40 acres, Scotts Run is the first step in a long-term effort to both organize and modernize the myriad utilities – water, sanitation, electric, etc. – as well as the roads, sidewalks, and mass transit systems required to support it.

“We’re laying the groundwork for every other phase of this massive project.”

“It’s a massive undertaking,” says John Adams, site superintendent and a 15-year company veteran. “We’re taking all the curved roads, overhead and underground utilities, and reengineering all of it into intelligent rectangular grids that will make everything easier to find and service in the future.”

Modernization efforts including expanding existing 12-inch waterlines to 24 inches, effectively doubling water capacities for the development’s anticipated 13 multi-story buildings (many as tall as 30-stories).

Adams likens Scott’s Run to the ‘crash test’ for all of Tyson’s Corner’s future rehabilitation efforts – “we’re literally laying the groundwork for every other phase of this project.”

TAC is uniquely suited to tackle such a project, thanks to the company’s impeccable reputations for safety, speed, and solving seemingly intractable challenges. Despite 15 different utilities running through the project footprint, for example, TAC has not experienced a single shutdown. “We’ve had to shift gears and reengineer solutions to countless unexpected problems,” said Adams, “but we’ve never stopped moving forward.”

TAC is uniquely suited to tackle such a project, thanks to the company’s impeccable reputations for safety, speed, and solving seemingly intractable challenges. Despite 15 different utilities running through the project footprint, for example, TAC has not experienced a single shutdown. “We’ve had to shift gears and reengineer solutions to countless unexpected problems,” said Adams, “but we’ve never stopped moving forward.”

A case-in-point: tasked with building a 6-foot underground sidewalk to run beneath a planned road, the team encountered significant challenges using automated boring equipment. The alternative? Adams and the TAC team hand-excavated the sidewalk using a makeshift trolley system reminiscent of a coal mine.

“We’re the little engine that could.”

“We roll up our sleeves and get involved – we don’t tell the owner ‘there’s a problem,’ we dive in and come up with a solution,” said Adams. “We don’t have the benefit of sitting around – time is of the essence and we buckle down and get it done.”

The work at Scott’s Run, in Adams’s estimation, perfectly embodies what makes The Anderson Company special. “We do a lot with a little. If I get a piece of equipment for a week, I’d better be done in a week because that equipment has to move on to the next job. We’re the little engine that could.”